Galvanized mesh fences are mostly made of galv. after weaving or welding meshes offering superior corrosion resistance property. An additional powder coating of plastic or vinyl is applied to galvanized fencing upon requst for additional durability and stronger corrosion protection. Supplied forms are Fence Mesh Rolls and Fence Mesh Panels.

We manufacture and supply gi wire mesh fences of two types, according to the fabric processing types:

Woven mesh fence

Welded mesh fence

Welded mesh fence is a rigid fence, while woven mesh fence is flexible mesh fence.

Woven mesh fence is further classified into:

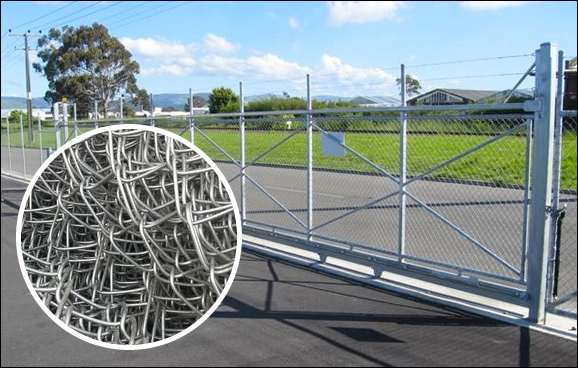

Chain link mesh fence ( For various border fence, perimeter fence, security fence, mobile fence, etc.), also called Rhomb mesh fence, or Diamond mesh fence.

Twisted woven mesh fence ( For poultry fencing and breeding), also called Hexagonal mesh fence or Poultry fence

Knot woven wire fence ( For livestock field, pasture and agriculture farming), also called Field fence, Horse fence, Cattle fence, Deer fence, Sheep and Goat Fence, Orchard Fence, etc.

Applications: Galvanized metal wire mesh fence are mainly used for Industrial, Commercial, Agricultural and Residential Perimeter Protection

Woven mesh fences with flexible structures are mainly used in poultry fencing, horse fencing, cattle fencing.

Chain link wire fence are mainly used in various perimeter and security fencing with barbed wire tops.

Welded wire fences are universal fencing products. Common welded mesh rolls are used for

border safety and protection. 358 welded mesh is popularly used as anti cut perimeter security fencing, mostly worked with concertina barbed wire coils.

Galvanized Mesh Fencing, with Hexagon hole, Diamond Hole, Square Hole, Rectangular Hole

Diamond Mesh Fencing of Galvanized and Anti Rust Coated Chain Link Fence Wire Mesh

Galvanized and green coated mesh fence, 2m height and 40m long each roll.

Specification as follows to SOMALIA:

Chain link type diamond mesh fabric, gauge 9 (.148"), wire mesh: 3mmx60mmx60mm, in rolls 2m height x 40m

Fence accessories: Galvanized post:

60mmx2600m(600mm buried into ground) , tension Wire: 3mm, binding wire

Color: All green

Expanded Metal Fence Panels

Diamond mesh expanded

Hexagon Mesh Rolled Fence

Hexagonal shape mesh fence rolls reinforced with supplemental horizontal wires, pvc coated, galv. or vinyl coated, in green, black and other colors.

Rectangular Hole 358 Mesh Type Welded Wire Panel Fence

Welded mesh panel and chain link mesh are both used in caging, fencing and barriers.

Examples follow.

Welded Mesh Cages for Dog Fencing

Chain Link Wire Mesh Animal Cages

Galvanized wire chained mesh, collapsible panel with gates

Woven mesh fence and welded mesh fence are both used in construction of general perimeter fencing and temporary mobile fencing. Examples follow.

Chain Link Perimeter Fencing

Welded Mesh Border Panel Fence

Welded mesh fence supplied in curved panels for garden and yard

Welded mesh fabric and chain link fabric are popularly used with barbed wire tops to form high security fencing solutions. Examples follow.

Barbed Wire Topped Chain Link Fence, Galvanized

Security fencing chain link mesh, galv., consisting of:

With barbed wire perimeter, post for gate

Y frame Steel posts to support linear rows of barbed wire, arm length 500 mm

With razor Wire top

Vehicle gates 4 mts x 8 meter wide, with padlock

Pedestrian gate with padlock

Welded Wire Fencing, Topped with Razor Blade Barbed Wire

Galvanised mesh fence, of welded panels, 2.4m high

Zinc coating: 230grams

Tensile strenghth: 850nmm2

Mesh welded in holes: 50mmx100mm

Wire diameter: 5.0mm

V-bend horizontal

With post galvanised

Overhang: 40x40mmx2.5mm

Barbed wire: Hot dipped razor barbed wire,

BTO-22x0.4mmx20mmx12mm

Galvanized fencing gates are supplied with galvanized fencing meshes to form a complete border / perimeter barrier system. Examples follow.

Weld Mesh Fencing Gates

Chain Link Fencing Gates

Galvanized fences are Electro Galvanized, Hot Dipped Galvanized, Galfan (Zinc-Aluminum) Galvanized, Galv. + Powder Coated.

Welded Mesh Fences, GBW and GAW.

Welded Mesh Fences GBW ( Galvanized Before Welded ), are made with pre-galvanized wire then welded into mesh panels.

Welded Mesh Fences

GAW (Galvanized After Welded), are welded with mild steel wire with no zinc coating and the galvanizing is done after the welded wire panel is formed.

Disadvantage and Advantage:

GBW welded wire fences cost less compared with GAW.

GWB welded mesh fences has one disadvantage: During the welding process of the GBW, the galvanizing at the weld spots, where the wires intersect, is burned away. This leaves places in the mesh that have lost the galvanizing protection against rust and corrosion. The weld locations are critical spots that tend to hold moisture longer than the individual wires. This can promote a more rapid decay, as rust eats into the unprotected steel. In interior locations, where the mesh or fence is not exposed to the elements, this is not as much of a problem. Heavier gauge wire will last longer due to the fact that it will take longer for rust to eat through the wire.

Welded mesh fences Galvanized After Weld (GAW) is stronger and durable. The mesh panels are made by dipping welded steel mesh sheet into a bath of molten zinc. The entire mesh panels, including the welded spots, are thoroughly coated with zinc plating against rust and corrosion. The GAW fence panels will last years longer compared with GBW and can be used in various severe conditions.

Woven Fences, GBW and GAW

Woven Wire Fences, Galvanized Before Weaving (GBW)

For woven fences (chain link, hinged or twisted), GBW means a process of Galvanized Before Weaving. Wire mesh Galvanized Before Weaving (GBW) is made with pre-galvanized wire, going through certain weaving process, forming a fabric. During the weaving process, certain spots of the mesh fabric may lose its galvanizing protection.

Woven Wire Fences, Galvanized After Weaving (GAW)

GAW is a process of weaving the fabric first, then the entire mesh sheets are soaked in a melt zinc galvanizing bath.

Galvanized woven fences, for example, hexagonal mesh fences, can be made with double galvanizing ( before and after) to ensure an excellent corrosion resisting property of the finished fences.

The steel wire or mesh becomes corrosion resistant after galvanizing processing. The galvanizing process made before weaving / welding or after, rendering the mesh fences different features.

Generally speaking, Galvanized woven fences and welded fences galv. after offers better corrosion protection and longer services life.

Firstly, Galvanized After Welding ( For welded mesh fences), and Galvanized After Weaving ( For woven mesh fences) enable the mesh fabrics a uniform surface treatment and complete corrosion protection. Galvanized before Welding (GBW) and Galvanizing Before Weaving (GBW) may have parts or spots where the galvanizing damaged during later mesh weave or weld processing.

Secondly, GAW costs higher compared with GBW process in general.

Thirdly, double galvanizing ( galvanized before and after), is available for some galvanized mesh fences with ensured superior corrosion protection.

Fencing Tops - For increasing security of steel fencing system

Concertina wire;

Flat razor wire panels;

Welded razor mesh;

Razor spikes.

We supply fences with a variety of processing and finishes according to application and customer demands.

Write to us and we are always ready to help.