Truss Mesh is made of steel wires / rods welded together to form a truss or ladder pattern, mainly used in construction reinforcement, especially in masonry construction of vertical wall works.

Material

Galvanized truss wire;

Truss mesh non galvanized steel;

Stainless steel truss wire.

Choosing truss wire materials:

Truss wire is often made from steel, galvanized or zinc coated for corrosion resistance.

Stainless steel truss wire is also available for more corrosive environments.

Non-galvanized truss wire can be used in some applications or environments where corrosion isn't a significant concern.

Truss Wire Structures

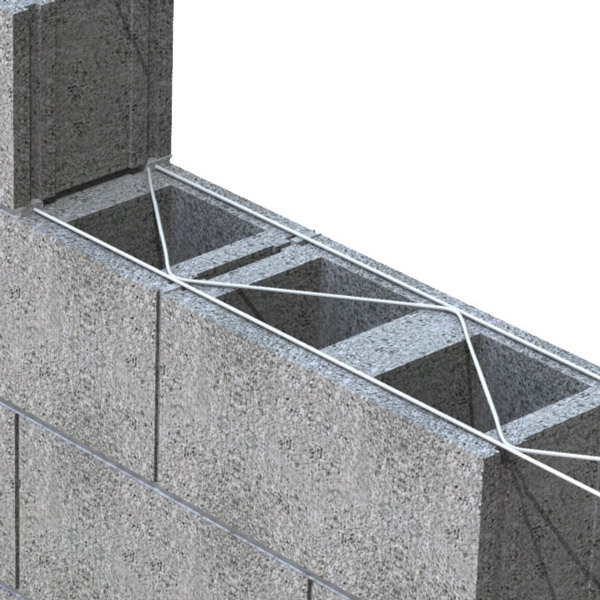

Truss mesh is made by welding of wires/bars/rods into deformed truss form / ladder mesh.

The mesh sheet is a two-dimensional wire lattice fabricated of longitudinal and diagonal wires.

Processing:

Longitudinal Wires: Primary load-bearing wires and run the length of the panel or roll.

Transverse Wires: These run perpendicular to the longitudinal wires and provide lateral support.

Diagonal Wires: In some truss wire configurations, diagonal wires are added to create the characteristic truss pattern, providing even more rigidity and strength to the overall structure.

The wires are welded together at their intersections, which ensures stability and strength.

Longitudinal and Transverse Wire Spacing: The spacing between the main longitudinal and transverse wires can range from 100mm to 300mm or more.

Sheet Dimensions: Truss wire products can come in sheets or rolls. Sheets can range in size, but common dimensions might include 2.4m x 6m or similar. Rolls can come in widths ranging from 1m to 2.4m and vary in length.

Weld Strength: The strength of the welds at the intersections of the wires is critical to the overall performance of the truss wire.

Where is Truss Mesh Used

Truss wire is commonly used for masonry and concrete wall reinforcement.

Truss wire mesh provides lateral stability and helps distribute stress. Truss wire is usually applied between layers of masonry or integrated into poured concrete walls, functioning as below:

1, Using of truss type welded wire reinforcement mesh can greatly reduces cracking that can arise from thermal stresses. This enhances resistance to water penetration, as cracks are controlled.

2, To increases lateral flexural strength.

3, To bond exterior and interior masonry together in composite or cavity walls. Also used to bond masonry at intersecting walls and corners.

In some applications, truss wire can be used in conjunction with 3D wire panels for additional reinforcement, especially in areas where extra strength is needed due to structural concerns.

Benefits of Galvanizing Truss Wire

Welded truss wire is a versatile construction material used in bridge and building construction due to its excellent load distribution properties:

Strength: The truss configuration provides higher strength-to-weight ratios than simple mesh patterns.

Flexibility: Despite their strength, these configurations can be rolled and unrolled, making them easier to transport and install.

Load Distribution: The truss design helps in spreading loads more evenly across the structure.

Corrosion Resistance

Longer Life: Galvanized truss wire will generally have a longer lifespan in corrosive environments compared to non-galvanized wire.

Better Performance in Concrete: Welded truss wire galvanized functions well when used for concrete reinforcement in the alkaline environment conditions.

Common wire diameter applied: 3mm-8mm / 2mm to 6mm

Popular size for export:

Welded truss wire: 3.7mm with side rods 100mm width x 3 m length

Welded Truss Wire Hot Dipped Galvanized

Truss mesh 91 ½ long

Block wall 14

Finish: Hot dipped galvanizing

Truss Mesh Reinforcement Panel

For New Zealand

Wire diameter 5.0mm

Panel width 20cm

Galvanized

Welded Truss Mesh of Heavy (1/4") Steel

Wire Truss Mesh for CMU reinforcement

Uncoated steel, non-galvanized

Truss Welded Mesh 4mm Diameter

Galvanized type

Wire diameter 4mm

Truss Wire: 8" CHB

Truss Wire: 4" CHB

10" x 120" Wire Trusses

Wire Trusses: Lox-all type wall reinforcement

Length 8ft(96") and 10ft(120")

Width: 5", 10"

Side rods and cross rods: 3/16" gauge mill galvanized wire

Wire standard: ASTM A82 with a finish that meets ASTM A41 and ASTM 82 requirement of a tensile strength 80,000 psi/yield area of 30%.

ASTM standards are established by the American Society for Testing and Materials, which is a globally recognized organization for developing and publishing technical standards for a wide range of materials, products, systems, and services.

ASTM A82: This specification generally refers to steel wire used in concrete reinforcement. The standard outlines the requirements for tensile strength, yield area, and other properties that the steel wire should meet. In truss wire, the reference to "ASTM A82," implies that the wire has been manufactured and tested to meet the requirements for tensile strength (80,000 psi) and other mechanical properties outlined in this standard.

ASTM A41: This standard deals with the finish or coating that may be applied to the metal. In truss wire production, ASTM A41 means the "mill galvanized wire" meets galvanized wire finish standard set this standard.